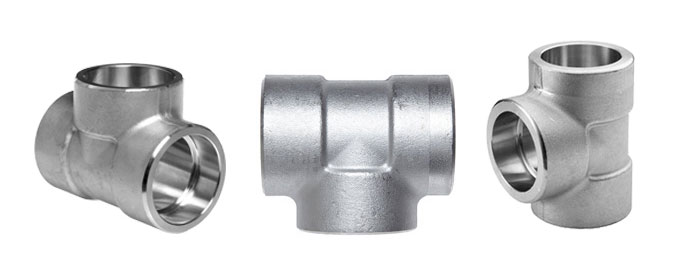

FORGED TEE PIPE FITTINGS, ASME FORGED TEE FITTINGS, FORGED REDUCING TEE, FORGED TEE MANUFACTURERS, FORGED LATERAL TEE, STAINLESS STEEL FORGED TEE, FORGED EQUAL TEE ,ASTM B16.9 FORGED TEE FITTINGS, FORGED TEE,FORGED TEE PIPE CONNECTIONS, CARBON STEEL FORGED TEE FITTINGS, FORGED TEE FITTINGS

The primary function of a tee fitting is to allow the movement of liquids or gases in multiple directions, making them useful in a variety of industrial applications.Tesco Steels specializes in manufacturing and exporting tee fittings that are extremely durable and corrosion-resistant, making them perfect for usage in harsh situations

Understanding Tee fittings

Tee fittings are essential components in industrial piping systems. These fittings are designed to connect three pipes, creating a T-shaped junction. The main purpose of a tee fitting is to allow the flow of liquids or gases in different directions, making them versatile for various industrial applications. The manufacturing process of Tee fittings involves shaping the metal through intense heat and pressure, resulting in a strong and reliable product. The construction ensures that these fittings have high strength and excellent resistance to corrosion and mechanical stress. Understanding the characteristics and benefits of Tee fittings is crucial in making an informed decision for your industrial needs.

When it comes to Tee fittings, there are several advantages that make them a popular choice in industrial settings. Firstly, the construction ensures superior strength and durability compared to other types of fittings. This makes them ideal for high-pressure applications where the fittings need to withstand extreme conditions. Additionally, Tee fittings offer excellent resistance to corrosion, which is crucial for industries dealing with corrosive fluids or environments. The smooth interior surface of fittings also minimizes friction loss, allowing for efficient flow of liquids or gases. Moreover, these fittings are available in a wide range of sizes, materials, and pressure ratings, making them suitable for various industrial applications. With their exceptional strength, durability, corrosion resistance, and versatility, Tee fittings are the go-to choice for many industries.

Different types of Tee fittings

When it comes to choosing the best forged tee fitting for your industrial needs, it's essential to understand the different types available.

The most common types of Tee fittings include socket weld, threaded, and butt-weld fittings.

Socket weld fittings are welded to the pipe by inserting the pipe into the socket of the fitting and applying heat to create a strong bond.

Threaded fittings, on the other hand, have threads on the inside and outside, allowing for easy installation by screwing them onto the pipes.

Butt-weld fittings require welding to connect the pipes, ensuring a secure and leak-free joint. Each type of forged tee fitting has its advantages and considerations, depending on the specific requirements of your industrial application. Understanding the different types will help you choose the right fitting for your needs.

Factors to consider when choosing Tee fittings

Choosing the best Tee fittings for your industrial needs requires careful consideration of several factors. Firstly, you need to assess the compatibility of the fitting with the pipes and fluids or gases in your system.

The material of the fitting should be compatible with the fluid or gas being transported to prevent corrosion or contamination. The pressure rating of the fitting is another crucial factor to consider.

Ensure that the fitting can handle the maximum pressure of your system to avoid any potential leaks or failures.

Size is also an important consideration, as the fitting should match the diameter of the pipes in your system.

Additionally, factors such as temperature, environment, and installation requirements should be taken into account. By evaluating these factors, you can choose Tee fittings that are perfectly suited for your industrial needs.

Materials used in Tee fittings

Tee fittings are made from a variety of materials, each offering unique properties and advantages. The choice of material depends on factors such as the system's operating conditions, the fluid being transported, and the budget. Some commonly used materials for Tee fittings include:

Carbon Steel

Carbon steel is a popular choice for Tee fittings due to its strength, durability, and affordability. It is suitable for a wide range of applications and can withstand high temperatures and pressures.

Stainless Steel

Stainless steel is known for its excellent corrosion resistance, making it ideal for applications where the fittings may come into contact with corrosive fluids or environments. It is also highly durable and can withstand extreme temperatures.

Alloy Steel

Alloy steel is a combination of carbon steel with other elements such as chromium, molybdenum, and nickel. This enhances its resistance to corrosion and makes it suitable for demanding applications where high strength and durability are required.

Brass

Brass is a copper-zinc alloy known for its excellent thermal and electrical conductivity. It is commonly used in plumbing systems where the fittings need to be resistant to dezincification, a form of corrosion that occurs in brass fittings exposed to certain water conditions.

These are just a few examples of the materials used in Tee fittings. The choice of material depends on the specific requirements of the plumbing system, including factors such as the fluid being transported, the operating temperature and pressure, and the desired lifespan of the fittings.

How to install Tee fittings

Proper installation of Tee fittings is essential for ensuring their optimal performance and longevity. The first step is to prepare the pipes by cutting them to the desired length and cleaning the ends to remove any dirt, debris, or burrs. Next, the fitting and pipes should be aligned to ensure a proper fit.

For socket weld fittings, the pipe should be inserted into the fitting socket until it reaches the bottom. Proper alignment is crucial to ensure a strong and leak-free joint. Once the fitting and pipe are aligned, the joint can be welded using the appropriate welding technique.

For threaded fittings, pipe threads should be coated with a suitable thread sealant or tape to prevent leaks. The fitting can then be screwed onto the pipe until it is tight. Butt-weld fittings require welding to connect the pipes, ensuring a secure and leak-free joint.

It is essential to follow industry standards and guidelines for the proper installation of Tee fittings to ensure their optimal performance and safety.

Common applications for Tee fittings

Tee fittings find applications in various industries where the efficient distribution or diversion of fluids or gases is required.

Some common applications include oil and gas pipelines, petrochemical plants, power generation facilities, chemical processing plants, and water treatment facilities.

In oil and gas pipelines, Tee fittings are used to create branch connections for distribution or diversion of oil or gas.

Petrochemical plants utilize these fittings for the safe and efficient transfer of chemicals and gases.

Power generation facilities employ Tee fittings in steam, gas, or water distribution systems.

Chemical processing plants rely on these fittings for the handling and transportation of corrosive fluids. Water treatment facilities use Tee fittings to control the flow and distribution of water. These are just a few examples of the many industries and applications where Tee fittings play a crucial role in ensuring the smooth operation of industrial processes.

Countries we export to: Tee Fittings Manufacturers / Suppliers / Stockist in Kuwait, Tee Fittings Manufacturers in UAE, Tee Fittings Manufacturers in Germany, Tee Fittings Manufacturers in Saudi Arabia, Tee Fittings Manufacturers in West Africa, Tee Fittings Manufacturers in Iraq, Tee Fittings Manufacturers in Congo, Tee Fittings Manufacturers in Mexico, Tee Fittings Manufacturers in Bahrain, Tee Fittings Manufacturers in Canada, Tee Fittings Manufacturers in Philippines, Tee Fittings Manufacturers in Thailand, Tee Fittings Manufacturers in Kenya, Tee Fittings Manufacturers in Oman, Tee Fittings Manufacturers in Malaysia, Tee Fittings Manufacturers in Turkey, Tee Fittings Manufacturers in Qatar, Tee Fittings Manufacturers in Sudan, Tee Fittings Manufacturers in Netherlands, Tee Fittings Manufacturers in Oman, Tee Fittings Manufacturers in Nigeria, Tee Fittings Manufacturers in Lithuania, Tee Fittings Manufacturers in Gabon, Tee Fittings Manufacturers in Russia, Tee Fittings Manufacturers in Vietnam, Tee Fittings Manufacturers in Angola, Tee Fittings Manufacturers in Bolivia, Tee Fittings Manufacturers in Indonesia, Tee Fittings Manufacturers in UK, Tee Fittings Manufacturers in Yemen, Tee Fittings Manufacturers in Italy, Tee Fittings Manufacturers in United States, Tee Fittings Manufacturers in Venezuela, Tee Fittings Manufacturers in Spain, Tee Fittings Manufacturers in Iran, Tee Fittings Manufacturers in Estonia, Tee Fittings Manufacturers in Kazakhstan, Tee Fittings Manufacturers in Algeria, Tee Fittings Manufacturers in Jordan, Tee Fittings Manufacturers in Ecuador, Tee Fittings Manufacturers in Portugal, Tee Fittings Manufacturers in Colombia, Tee Fittings Manufacturers in Libya, Tee Fittings Manufacturers in Chile, Tee Fittings Manufacturers in Peru, Tee Fittings Manufacturers in Iran, Tee Fittings Manufacturers in South Africa, Tee Fittings Manufacturers in Bangkok, Tee Fittings Manufacturers in Namibia, Tee Fittings Manufacturers in Jeddah, Tee Fittings Manufacturers in Afghanistan, Tee Fittings Manufacturers in Israel, Tee Fittings Manufacturers in Zambia, Tee Fittings Manufacturers in Macau, Tee Fittings Manufacturers in Morocco, Tee Fittings Manufacturers in Denmark, Tee Fittings Manufacturers in Taiwan, Tee Fittings Manufacturers in Norway, Tee Fittings Manufacturers in Belarus, Tee Fittings Manufacturers in North Macedonia, Tee Fittings Manufacturers in Lebanon, Tee Fittings Manufacturers in Sri Lanka, Tee Fittings Manufacturers in Bhutan, Tee Fittings Manufacturers in Bulgaria, Tee Fittings Manufacturers in Albania, Tee Fittings Manufacturers in Ukraine, Tee Fittings Manufacturers in Belgium, Tee Fittings Manufacturers in Finland, Tee Fittings Manufacturers in Slovokia, Tee Fittings Manufacturers in Tibet, Tee Fittings Manufacturers in Romania, Tee Fittings Manufacturers in France, Tee Fittings Manufacturers in Brazil, Tee Fittings Manufacturers in Trinidad & Tobago, Tee Fittings Manufacturers in Fiji, Tee Fittings Manufacturers in Tunisia, Tee Fittings Manufacturers in Gambia, Tee Fittings Manufacturers in Mexico, Tee Fittings Manufacturers in Hungary, Tee Fittings Manufacturers in Zimbabwe, Tee Fittings Manufacturers in Mongolia, Tee Fittings Manufacturers in Ghana, Tee Fittings Manufacturers in Egypt, Tee Fittings Manufacturers in Kazakhstan, Tee Fittings Manufacturers in Czech Republic, Tee Fittings Manufacturers in Azerbaijan, Tee Fittings Manufacturers in Poland, Tee Fittings Manufacturers in Greece, Tee Fittings Manufacturers in Costa Rica, Tee Fittings Manufacturers in Kosovo, Tee Fittings Manufacturers in New Zealand, Tee Fittings Manufacturers in Croatia, Tee Fittings Manufacturers in Puerto Rico, Tee Fittings Manufacturers in Tanzania, Tee Fittings Manufacturers in Somalia.

Major Exporting Areas: TeeFittings Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, Alloy 20 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.

SPECIFICATIONS

STAINLESS STEEL: 310, 304, 304H, 304L, 316, 316L, 321, RA330

INCONEL: 600, 601, 602CA, 625, 690, 800, 800H, 800HT

MONEL: 400, K500

HASTELLOY: C276, C22

253MA

3mm - 18mm

CUSTOMIZED