Insulation Pins Manufacturer, Insulation Pins Steel Manufacturer, Insulation Pins steel Manufacturer, Insulation Pins Manufacturer, Insulation Pins

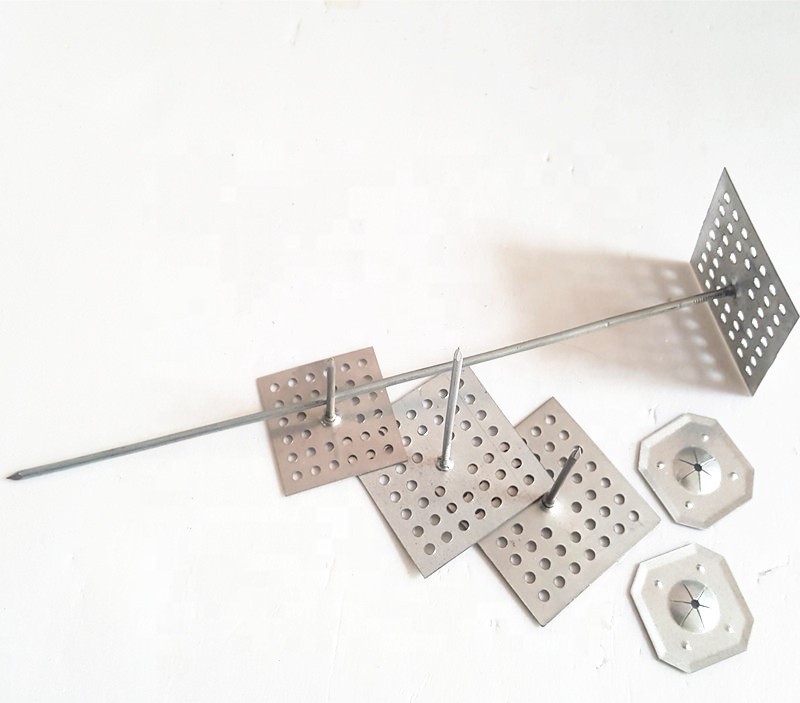

Insulation Pins are used to mechanically fix and install insulation material that can be pierced by metal spindles. Insulaton Pins, also referred as 'hanger pins', are either stud-weldable, or designed to be bonded with adhesive for non-welded systems.

Dimensions of Insulation Pins

The dimensions of insulation pins are according to METALX standard part numbers or customer specifications / drawing. METALX ENGINEERING INC is capable of manufacturing all types of insulation pins with precise dimensions.

What are Insulation Pins?

Insulation pins are a crucial tool for securing different kinds of insulation materials. In some circumstances, particularly with industrial insulation, these fasteners may also be referred to as stud welding pins or simply studs. Other names for these fasteners include insulation nails, insulation studs and insulation nails. Insulation pins are made from a variety of materials and come in a variety of sizes and diameters. Additionally available are self-adhesive insulating pins. Everything is dependent on the particular application and operating temperature range of the insulating substance.

Whether the insulation is in the form of a mat, blanket, or board, insulation pins aid in keeping it in place. Insulation is held in place by pins both vertically and horizontally. Insulation pins make it possible for insulation material to adhere tightly to the insulating material. Additionally, insulation pins stop insulation from drooping. Products including mineral wool, stone wool, glass wool, ceramic wool, aerogel, PIR, and PUR are secured using insulation pins. Insulation pins must be installed properly and be specifically tailored for their intended usage in order for them to function properly.

Insulation pins are available in a range of lengths and diameters. The size of your insulation pins should be chosen once you have chosen the appropriate material. In most circumstances, the insulation thickness, service temperature, and corresponding loads would be taken into consideration. Typically, insulation pins with a diameter of 3mm or 4mm are used to insulate HVAC components.

Different Types of Insulation Pins

Insulation pins come in various types, each designed for specific insulation materials and installation requirements. Understanding the different types of insulation pins will help you make an informed decision and ensure the best fit for your project. Let's take a closer look at some of the most common types:

Stick Pins

Stick pins are one of the most basic types of insulation pins. They are typically used for securing lightweight insulation materials, such as fiberglass or mineral wool, to metal surfaces. Stick pins consist of a metal pin with a washer attached to one end and a self-locking cap on the other end. The pin is inserted through the insulation material and into the metal surface, with the washer providing stability and preventing the pin from pulling through. Stick pins are easy to install and cost-effective, making them a popular choice for residential insulation projects.

Self-Stick Pins

Self-stick pins, also known as peel-and-stick pins, are a convenient option for attaching insulation materials to metal surfaces. They are pre-coated with adhesive on one side, allowing for easy installation without the need for additional tools or adhesives. Self-stick pins are commonly used for lightweight insulation materials in HVAC ductwork and equipment. However, it's important to ensure proper surface preparation for optimal adhesion and long-term performance.

Weld Pins

Weld pins are designed for attaching insulation materials to metal surfaces through welding. They consist of a pin with a weld base that is welded directly onto the metal surface. Weld pins provide excellent stability and are commonly used for heavy-duty insulation applications, such as industrial boilers and piping systems. The welded connection ensures a strong bond and prevents the insulation from shifting or coming loose over time.

Cup Head Pins

Cup head pins, also known as Lacing Anchors, are specifically designed for attaching insulation materials to mechanical equipment, such as turbines, generators, and tanks. They feature a cup-shaped head that provides a larger surface area for secure attachment. Cup head pins are typically installed by welding onto the equipment surface or by using an adhesive or mechanical fastener. Their robust design and secure attachment make them suitable for high-temperature and high-vibration environments.

Quilting Pins

Quilting pins are used for securing insulation materials with facing or jacketing, such as foil-faced fiberglass or vinyl-faced insulation. They consist of a pin with a washer attached to one end and a quilted base plate on the other end. The quilted base plate is designed to hold the insulation facing or jacketing in place, providing a neat and secure finish. Quilting pins are commonly used in commercial and industrial applications, where aesthetics and appearance are important.

These are just a few examples of the different types of insulation pins available in the market. Each type has its unique advantages and applications, so it's essential to consider factors such as the type of insulation material, surface, and environmental conditions when choosing the right insulation pins for your project.

Factors to Consider When Choosing Insulation Pins

Choosing the right insulation pins involves considering various factors to ensure the best fit for your project. Here are some key factors to keep in mind:

Insulation Material

The type of insulation material you're using will determine the compatibility and requirements for insulation pins. Different materials have different characteristics, such as weight, thickness, and composition, which can impact the choice of insulation pins. For example, lightweight materials may require stick pins, while heavy-duty materials may require weld pins for secure attachment. Consider the specific properties of your insulation material to select the appropriate insulation pins.

Surface Type

The surface you're attaching the insulation to also plays a crucial role in determining the type of insulation pins required. Metal surfaces, such as ductwork or equipment, may require different insulation pins than concrete or wood surfaces. Factors such as surface texture, temperature, and moisture levels should be taken into account when choosing the right insulation pins for optimal performance and longevity.

Environmental Conditions

Consider the environmental conditions in which the insulation pins will be installed. Factors such as temperature, humidity, and exposure to chemicals or corrosive substances can affect the performance and lifespan of insulation pins. In extreme conditions, special insulation pins with corrosion-resistant coatings or materials may be required. It's important to select insulation pins that can withstand the specific environmental challenges of your project to ensure long-term efficiency.

Installation Method

The method of installation is another crucial factor to consider when choosing insulation pins. Some insulation pins require welding, while others can be attached using adhesives or mechanical fasteners. Depending on your project requirements and available resources, select insulation pins that align with the preferred installation method. It's also important to ensure proper installation techniques and follow manufacturer guidelines for optimal performance.

By considering these factors and assessing your project requirements, you can choose the right insulation pins that will deliver optimal energy efficiency and cost savings.

Common Insulation Pin Materials and Their Benefits

Insulation pins are available in various materials, each with its unique benefits and applications. The choice of insulation pin material depends on factors such as the insulation material, surface type, and environmental conditions. Let's take a closer look at some common insulation pin materials and their advantages:

Stainless Steel

Stainless steel is a popular choice for insulation pins due to its durability, corrosion resistance, and strength. Stainless steel pins are suitable for a wide range of applications, including HVAC ductwork, equipment insulation, and industrial settings. They can withstand high temperatures, moisture, and exposure to chemicals, making them ideal for harsh environments. Stainless steel insulation pins provide long-term performance and are resistant to rust, ensuring the integrity and stability of the insulation system.

Galvanized Steel

Galvanized steel pins are another commonly used option for insulation applications. They are coated with a layer of zinc to enhance corrosion resistance. Galvanized steel pins offer excellent strength and stability, making them suitable for heavy-duty insulation materials and industrial settings. They are cost-effective and provide reliable performance in various environmental conditions.

Aluminum

Aluminum insulation pins are lightweight, yet strong and durable. They are often used for attaching insulation materials to metal surfaces, such as HVAC ductwork. Aluminum pins offer good corrosion resistance and are easy to handle and install. They are a cost-effective option for residential and commercial insulation projects where weight is a consideration.

Plastic

Plastic insulation pins, typically made from high-density polyethylene (HDPE), are lightweight and easy to install. They are commonly used for securing lightweight insulation materials in residential applications. Plastic pins offer good corrosion resistance and are suitable for non-metal surfaces, such as wood or concrete. However, they may not be suitable for high-temperature or heavy-duty applications.

These are just a few examples of the common insulation pin materials available. Each material has its advantages and suitability for specific applications. Consider the specific requirements of your project, including environmental conditions and compatibility with the insulation material, when selecting the right insulation pin material.

Installation Process for Insulation Pins

Proper installation techniques are crucial for the effective performance of insulation pins and the overall insulation system. Follow these steps for a successful insulation pin installation:

Preparation

Ensure the surface is clean, dry, and free from debris or contaminants. Proper surface preparation is essential for optimal adhesion and stability. If required, apply a primer or adhesive promoter to enhance the bond between the insulation pin and the surface.

Layout and Placement

Determine the layout and spacing of the insulation pins based on the insulation material's requirements and the surface area to be covered. Consider factors such as the insulation material's weight, thickness, and thermal expansion. Mark the locations for the insulation pins, ensuring they are evenly spaced and provide adequate support for the insulation material.

Attachment

Depending on the insulation pin type, attach the pins using the appropriate installation method. Stick pins or self-stick pins can be inserted directly through the insulation material and into the surface. Weld pins require welding onto the surface, following recommended welding techniques. Cup head pins may require adhesive or mechanical fasteners in addition to welding. Follow manufacturer guidelines and ensure proper attachment for maximum stability and longevity.

Secure Attachment

After attaching the insulation pins, ensure they are securely fastened and provide adequate support to prevent sagging or shifting of the insulation material. Check for any loose or improperly installed pins and make necessary adjustments. Proper attachment is crucial for maintaining the insulation system's integrity and maximizing energy efficiency.

Final Checks

Once the insulation pins are installed, conduct a thorough inspection to ensure proper attachment and alignment. Check for any gaps or areas where the insulation material may be compressed or compromised. Address any issues promptly to maintain the desired Resistance value and prevent energy loss.

Countries we export to: Insulation Pins Manufacturers / Suppliers / Stockist in Kuwait, Insulation Pins Manufacturers in UAE, Insulation Pins Manufacturers in Germany, Insulation Pins Manufacturers in Saudi Arabia, Insulation Pins Manufacturers in West Africa, Insulation Pins Manufacturers in Iraq, Insulation Pins Manufacturers in Congo, Insulation Pins Manufacturers in Mexico, Insulation Pins Manufacturers in Bahrain, Insulation Pins Manufacturers in Canada, Insulation Pins Manufacturers in Philippines, Insulation Pins Manufacturers in Thailand, Insulation Pins Manufacturers in Kenya, Insulation Pins Manufacturers in Oman, Insulation Pins Manufacturers in Malaysia, Insulation Pins Manufacturers in Turkey, Insulation Pins Manufacturers in Qatar, Insulation Pins Manufacturers in Sudan, Insulation Pins Manufacturers in Netherlands, Insulation Pins Manufacturers in Oman, Insulation Pins Manufacturers in Nigeria, Insulation Pins Manufacturers in Lithuania, Insulation Pins Manufacturers in Gabon, Insulation Pins Manufacturers in Russia, Insulation Pins Manufacturers in Vietnam, Insulation Pins Manufacturers in Angola, Insulation Pins Manufacturers in Bolivia, Insulation Pins Manufacturers in Indonesia, Insulation Pins Manufacturers in UK, Insulation Pins Manufacturers in Yemen, Insulation Pins Manufacturers in Italy, Insulation Pins Manufacturers in United States, Insulation Pins Manufacturers in Venezuela, Insulation Pins Manufacturers in Spain, Insulation Pins Manufacturers in Iran, Insulation Pins Manufacturers in Estonia, Insulation Pins Manufacturers in Kazakhstan, Insulation Pins Manufacturers in Algeria, Insulation Pins Manufacturers in Jordan, Insulation Pins Manufacturers in Ecuador, Insulation Pins Manufacturers in Portugal, Insulation Pins Manufacturers in Colombia, Insulation Pins Manufacturers in Libya, Insulation Pins Manufacturers in Chile, Insulation Pins Manufacturers in Peru, Insulation Pins Manufacturers in Iran, Insulation Pins Manufacturers in South Africa, Insulation Pins Manufacturers in Bangkok, Insulation Pins Manufacturers in Namibia, Insulation Pins Manufacturers in Jeddah, Insulation Pins Manufacturers in Afghanistan, Insulation Pins Manufacturers in Israel, Insulation Pins Manufacturers in Zambia, Insulation Pins Manufacturers in Macau, Insulation Pins Manufacturers in Morocco, Insulation Pins Manufacturers in Denmark, Insulation Pins Manufacturers in Taiwan, Insulation Pins Manufacturers in Norway, Insulation Pins Manufacturers in Belarus, Insulation Pins Manufacturers in North Macedonia, Insulation Pins Manufacturers in Lebanon, Insulation Pins Manufacturers in Sri Lanka, Insulation Pins Manufacturers in Bhutan, Insulation Pins Manufacturers in Bulgaria, Insulation Pins Manufacturers in Albania, Insulation Pins Manufacturers in Ukraine, Insulation Pins Manufacturers in Belgium, Insulation Pins Manufacturers in Finland, Insulation Pins Manufacturers in Slovokia, Insulation Pins Manufacturers in Tibet, Insulation Pins Manufacturers in Romania, Insulation Pins Manufacturers in France, Insulation Pins Manufacturers in Brazil, Insulation Pins Manufacturers in Trinidad & Tobago, Insulation Pins Manufacturers in Fiji, Insulation Pins Manufacturers in Tunisia, Insulation Pins Manufacturers in Gambia, Insulation Pins Manufacturers in Mexico, Insulation Pins Manufacturers in Hungary, Insulation Pins Manufacturers in Zimbabwe, Insulation Pins Manufacturers in Mongolia, Insulation Pins Manufacturers in Ghana, Insulation Pins Manufacturers in Egypt, Insulation Pins Manufacturers in Kazakhstan, Insulation Pins Manufacturers in Czech Republic, Insulation Pins Manufacturers in Azerbaijan, Insulation Pins Manufacturers in Poland, Insulation Pins Manufacturers in Greece, Insulation Pins Manufacturers in Costa Rica, Insulation Pins Manufacturers in Kosovo, Insulation Pins Manufacturers in New Zealand, Insulation Pins Manufacturers in Croatia, Insulation Pins Manufacturers in Puerto Rico, Insulation Pins Manufacturers in Tanzania, Insulation Pins Manufacturers in Somalia.

Major Exporting Areas: Insulation Pins Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, Alloy 20 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.

SPECIFICATIONS

STAINLESS STEEL: 310, 304, 304H, 304L, 316, 316L, 321, RA330

INCONEL: 600, 601, 602CA, 625, 690, 800, 800H, 800HT

MONEL: 400, K500

HASTELLOY: C276, C22

253MA

- High temperature stability

- Aids erosion resistance

- Superior retention

- Support insulation