Partial Threaded Stud Manufacturer, Stainless Steel Partial Threaded Stud Manufacturer, Partial Threaded Stud Manufacturer, Partial Threaded Stud Anchor Manufacturer, Partial Threaded Stud Anchor Manufacturer, 304 Partial Threaded Stud, 310 Partial Threaded Stud, 316 Partial Threaded Stud, UNC Threaded Partial Threaded Stud, Threaded Partial Threaded Stud, Partial Threaded Stud with Hex Nuts

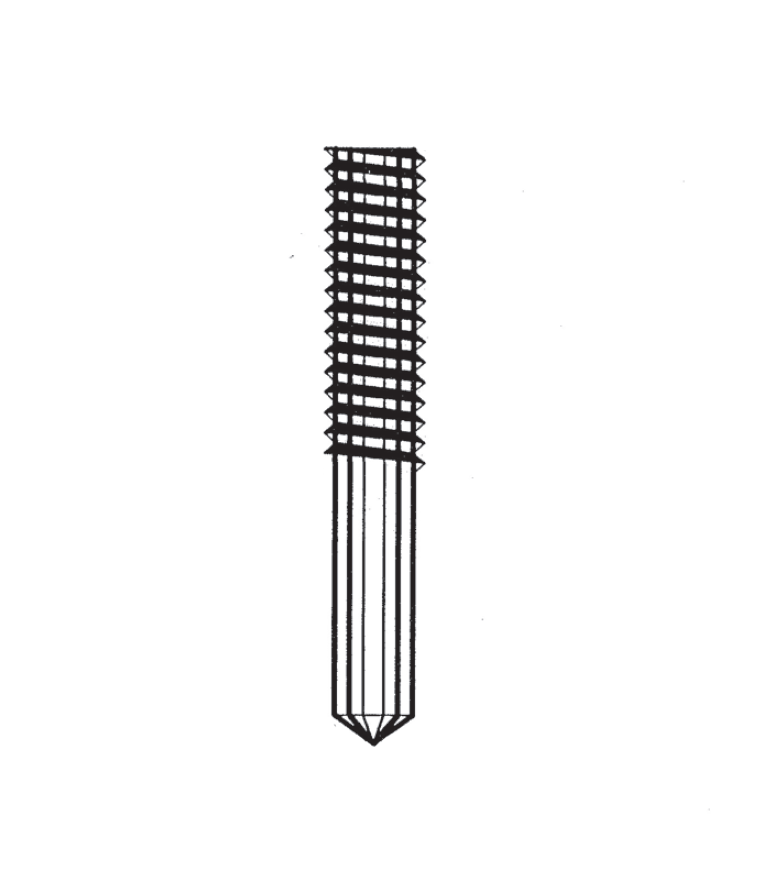

Partial Threaded Studs are manufactured from round bars. Partial Threaded Studs are cut in the appropriate length and then threaded and machined according to the dimensions with precision machinery. We supply these partial threaded studs with or without nuts.

Dimensions of Partial Threaded Studs

The dimensions of partial threaded studs are according to METALX standard part numbers or customer specifications / drawing. METALX ENGINEERING INC is capable of manufacturing all types of partial threaded studs with precise dimensions.

The Role of Partial Threaded Studs in Ensuring Safety and Efficiency in Industrial Settings

In the fast-paced and demanding world of industrial operations, safety and efficiency are paramount. One crucial element that often goes unnoticed but plays a vital role in ensuring both is Partial Threaded Studs. These small, yet essential components are the unsung heroes that keep refractory materials securely in place, preventing potential accidents and optimizing performance. Partial Threaded Studs act as a sturdy support system, allowing for the proper installation and stability of high-temperature linings in industrial settings such as furnaces, boilers, and kilns. By effectively anchoring the refractory materials to the underlying structure, they provide resistance against thermal expansion and contraction, vibration, and mechanical stress. This not only enhances safety by reducing the risk of refractory failure but also improves operational efficiency by maintaining optimal heat transfer, reducing energy consumption, and extending the service life of the equipment. When it comes to safeguarding personnel, equipment, and profits, Partial Threaded Studs are an indispensable component that should never be overlooked.

Importance of Heat Management in Industrial Applications

Efficient heat management is crucial in various industrial applications. Whether it's in steel manufacturing, cement production, or power generation, controlling and optimizing heat is essential for operational efficiency, product quality, and equipment durability. Excessive heat can lead to refractory lining failure, decreased productivity, and increased maintenance costs. That's where Partial Threaded Studs refractory anchors come into play. Partial Threaded Studs refractory anchors play a vital role in heat management by securing refractory linings in place, preventing them from shifting or falling off due to thermal expansion and contraction. By maintaining the integrity of the refractory lining, Partial Threaded Studs refractory anchors ensure even distribution of heat, reducing the risk of hot spots and thermal stress. This not only enhances the overall performance of the equipment but also prolongs its lifespan, saving businesses time and money in the long run.

Factors to Consider When Selecting Partial Threaded Studs

Selecting the right Partial Threaded Studs refractory anchor is crucial for optimal heat management and durability. Several factors need to be considered to ensure the anchor's compatibility with the refractory lining and the operating conditions. Here are some key factors to keep in mind during the selection process:

Temperature Range

Different Partial Threaded Studs refractory anchors have varying temperature limits. It's crucial to choose an anchor that can withstand the maximum operating temperature of your application without compromising its integrity.

Refractory Lining Thickness

The thickness of the refractory lining determines the type and size of Partial Threaded Studs refractory anchor required. Consider the thickness of the lining and ensure the anchor's length is sufficient to penetrate through the lining while maintaining a secure grip.

Substrate Material

The type of substrate material can affect the choice of Partial Threaded Studs refractory anchor. For example, stainless steel anchors are suitable for most applications, but in corrosive environments, corrosion-resistant alloys may be required.

Thermal Expansion

Consider the coefficient of thermal expansion of both the refractory lining and the Partial Threaded Studs refractory anchor. A mismatch in thermal expansion coefficients can cause stress and lead to anchor failure or refractory lining cracking.

Installation Method

Different Partial Threaded Studs refractory anchors require specific installation techniques, such as welding, mechanical attachment, or adhesive bonding. Consider the available installation methods and choose an anchor that aligns with your capabilities and requirements.

Installation of Partial Threaded Studs

Proper installation is essential for the effective performance and longevity of Partial Threaded Studs refractory anchors. Here are some key guidelines to follow during installation:

Surface Preparation

Ensure the substrate surface is clean, dry, and free from any contaminants to achieve a strong bond between the baseplate and the substrate. Remove any loose material or rust using suitable methods such as wire brushing or sandblasting.

Anchor Placement

Position the Partial Threaded Studs refractory anchors at the recommended spacing to achieve uniform support and load distribution. Follow the manufacturer's guidelines for anchor placement to ensure optimal performance.

Mechanical Attachment

Depending on the anchor type, use appropriate methods such as welding, bolting, or adhesive bonding to secure the baseplate to the substrate. Follow industry best practices and manufacturer recommendations for the specific installation method.

Refractory Lining Installation

Once the baseplates are securely attached, install the refractory lining around the Partial Threaded Studs refractory anchors. Ensure proper alignment and contact between the lining and the anchors to maximize their effectiveness.

Maintenance of Partial Threaded Studs

Proper maintenance is essential for the effective performance and longevity of Partial Threaded Studs refractory anchors.

Regular Inspections

Conduct routine inspections to identify any signs of anchor damage, refractory lining wear, or movement. Inspections should be performed at regular intervals or after any maintenance shutdowns to ensure early detection of potential issues.

Cleaning and Repair

Remove any debris or build-up around the Partial Threaded Studs refractory anchors using suitable cleaning methods. Repair any damaged or worn-out anchors promptly to maintain the integrity of the refractory lining.

Refractory Lining Maintenance

Follow the recommended practices for refractory lining maintenance, including patching, reapplication, or replacement as necessary. Properly maintained refractory linings enhance the performance and lifespan of Partial Threaded Studs refractory anchors.

Enhancing Durability with Proper Anchor Design and Material Selection

The design and material selection of Partial Threaded Studs refractory anchors play a crucial role in their durability and effectiveness. When it comes to anchor design, factors such as the shape, length, and spacing of the Partial Threaded Studs, as well as the size and thickness of the baseplate, must be considered. The design should ensure secure anchorage and load distribution while minimizing stress concentration and thermal shock.

In terms of material selection, stainless steel is the most commonly used material for Partial Threaded Studs refractory anchors due to its excellent heat resistance and mechanical strength. However, in corrosive environments, it may be necessary to use corrosion-resistant alloys or coatings to ensure long-term durability.

Consulting with experienced refractory experts or manufacturers can provide valuable insights into proper anchor design and material selection for your specific application, ensuring enhanced durability and performance.

Applications of Partial Threaded Studs

The use of Partial Threaded Studs is prevalent in various industries that require high-temperature resistant linings. Some of the industries that benefit from Partial Threaded Studs include:

Steel and Metal

Steel mills and metal processing facilities rely on refractory linings to withstand the extreme temperatures involved in the production process. Partial Threaded Studs ensure the stability and longevity of these linings, contributing to the efficiency and safety of the operations.

Power Generation

Power plants, including coal-fired, gas-fired, and nuclear plants, use refractory linings in boilers, furnaces, and chimneys. Partial Threaded Studs play a vital role in maintaining the integrity of these linings, ensuring the reliable operation of the power generation facilities.

Cement and Lime

The cement and lime industry involves high-temperature processes, such as kilns and preheaters. Partial Threaded Studs are essential in securing the refractory linings and preventing any failure or collapse that could disrupt the production process.

Petrochemical

Petrochemical plants, including refineries and chemical processing facilities, require refractory linings in various units such as reactors, furnaces, and incinerators. Partial Threaded Studs are crucial in maintaining the performance and safety of these units under harsh operating conditions.

Benefits of Using Partial Threaded Studs

The use of Partial Threaded Studs offers numerous benefits for industrial applications. Understanding these benefits can help you appreciate the value and importance of these anchors. Here are some key advantages of using stainless steel Partial Threaded Studs:

Corrosion Resistance

Partial Threaded Studs offer excellent resistance to corrosion, making them suitable for a wide range of environments. They can withstand exposure to moisture, chemicals, and high temperatures, ensuring long-lasting performance and durability.

High-Temperature Resistance

Partial Threaded Studs can withstand extreme heat, making them ideal for applications that involve exposure to intense thermal conditions.

Mechanical Stability

Partial Threaded Studs provide strong mechanical stability to refractory linings, preventing movement or displacement. They ensure that the refractory material remains securely in place, even under high mechanical stress or vibration.

Versatility

Partial Threaded Studs are versatile and can be used in various industrial applications. They are suitable for use in furnaces, boilers, kilns, chimneys, and other structures that require refractory linings.

Longevity

Anchors are highly durable and have a long lifespan, even in harsh environments. Their resistance to corrosion, high temperatures, and mechanical stress ensures that they can withstand the test of time, reducing the need for frequent repairs or replacements.

Countries we export to: Partial Threaded Stud Manufacturers / Suppliers / Stockist in Kuwait, Partial Threaded Stud Manufacturers in UAE, Partial Threaded Stud Manufacturers in Germany, Partial Threaded Stud Manufacturers in Saudi Arabia, Partial Threaded Stud Manufacturers in West Africa, Partial Threaded Stud Manufacturers in Iraq, Partial Threaded Stud Manufacturers in Congo, Partial Threaded Stud Manufacturers in Mexico, Partial Threaded Stud Manufacturers in Bahrain, Partial Threaded Stud Manufacturers in Canada, Partial Threaded Stud Manufacturers in Philippines, Partial Threaded Stud Manufacturers in Thailand, Partial Threaded Stud Manufacturers in Kenya, Partial Threaded Stud Manufacturers in Oman, Partial Threaded Stud Manufacturers in Malaysia, Partial Threaded Stud Manufacturers in Turkey, Partial Threaded Stud Manufacturers in Qatar, Partial Threaded Stud Manufacturers in Sudan, Partial Threaded Stud Manufacturers in Netherlands, Partial Threaded Stud Manufacturers in Oman, Partial Threaded Stud Manufacturers in Nigeria, Partial Threaded Stud Manufacturers in Lithuania, Partial Threaded Stud Manufacturers in Gabon, Partial Threaded Stud Manufacturers in Russia, Partial Threaded Stud Manufacturers in Vietnam, Partial Threaded Stud Manufacturers in Angola, Partial Threaded Stud Manufacturers in Bolivia, Partial Threaded Stud Manufacturers in Indonesia, Partial Threaded Stud Manufacturers in UK, Partial Threaded Stud Manufacturers in Yemen, Partial Threaded Stud Manufacturers in Italy, Partial Threaded Stud Manufacturers in United States, Partial Threaded Stud Manufacturers in Venezuela, Partial Threaded Stud Manufacturers in Spain, Partial Threaded Stud Manufacturers in Iran, Partial Threaded Stud Manufacturers in Estonia, Partial Threaded Stud Manufacturers in Kazakhstan, Partial Threaded Stud Manufacturers in Algeria, Partial Threaded Stud Manufacturers in Jordan, Partial Threaded Stud Manufacturers in Ecuador, Partial Threaded Stud Manufacturers in Portugal, Partial Threaded Stud Manufacturers in Colombia, Partial Threaded Stud Manufacturers in Libya, Partial Threaded Stud Manufacturers in Chile, Partial Threaded Stud Manufacturers in Peru, Partial Threaded Stud Manufacturers in Iran, Partial Threaded Stud Manufacturers in South Africa, Partial Threaded Stud Manufacturers in Bangkok, Partial Threaded Stud Manufacturers in Namibia, Partial Threaded Stud Manufacturers in Jeddah, Partial Threaded Stud Manufacturers in Afghanistan, Partial Threaded Stud Manufacturers in Israel, Partial Threaded Stud Manufacturers in Zambia, Partial Threaded Stud Manufacturers in Macau, Partial Threaded Stud Manufacturers in Morocco, Partial Threaded Stud Manufacturers in Denmark, Partial Threaded Stud Manufacturers in Taiwan, Partial Threaded Stud Manufacturers in Norway, Partial Threaded Stud Manufacturers in Belarus, Partial Threaded Stud Manufacturers in North Macedonia, Partial Threaded Stud Manufacturers in Lebanon, Partial Threaded Stud Manufacturers in Sri Lanka, Partial Threaded Stud Manufacturers in Bhutan, Partial Threaded Stud Manufacturers in Bulgaria, Partial Threaded Stud Manufacturers in Albania, Partial Threaded Stud Manufacturers in Ukraine, Partial Threaded Stud Manufacturers in Belgium, Partial Threaded Stud Manufacturers in Finland, Partial Threaded Stud Manufacturers in Slovokia, Partial Threaded Stud Manufacturers in Tibet, Partial Threaded Stud Manufacturers in Romania, Partial Threaded Stud Manufacturers in France, Partial Threaded Stud Manufacturers in Brazil, Partial Threaded Stud Manufacturers in Trinidad & Tobago, Partial Threaded Stud Manufacturers in Fiji, Partial Threaded Stud Manufacturers in Tunisia, Partial Threaded Stud Manufacturers in Gambia, Partial Threaded Stud Manufacturers in Mexico, Partial Threaded Stud Manufacturers in Hungary, Partial Threaded Stud Manufacturers in Zimbabwe, Partial Threaded Stud Manufacturers in Mongolia, Partial Threaded Stud Manufacturers in Ghana, Partial Threaded Stud Manufacturers in Egypt, Partial Threaded Stud Manufacturers in Kazakhstan, Partial Threaded Stud Manufacturers in Czech Republic, Partial Threaded Stud Manufacturers in Azerbaijan, Partial Threaded Stud Manufacturers in Poland, Partial Threaded Stud Manufacturers in Greece, Partial Threaded Stud Manufacturers in Costa Rica, Partial Threaded Stud Manufacturers in Kosovo, Partial Threaded Stud Manufacturers in New Zealand, Partial Threaded Stud Manufacturers in Croatia, Partial Threaded Stud Manufacturers in Puerto Rico, Partial Threaded Stud Manufacturers in Tanzania, Partial Threaded Stud Manufacturers in Somalia.

Major Exporting Areas: Partial Threaded Stud Anchors Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, Alloy 20 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.

SPECIFICATIONS

STAINLESS STEEL: 310, 304, 304H, 304L, 316, 316L, 321, RA330

INCONEL: 600, 601, 602CA, 625, 690, 800, 800H, 800HT

MONEL: 400, K500

HASTELLOY: C276, C22

3mm - 50mm

THREADED / SHARPENED

CUSTOMIZED