BRIGHT

POLISHED

COATED

MATT FINISH

We, MetalX Engineering Inc, are the leading manufacturers, supplier and exporter of a commendable quality SS 304H Threadolet at the most affordable price. We focus on offering the best quality A182 F304H Threadolet that meet the national and international quality standards. We fulfil the demands of our clients by providing them with dimensionally accurate products. In the industrial manufacturing field, we are abundantly appreciated for giving a standard product that offers complete satisfaction service. We, MetalX Engineering Inc, have separate teams of experts and a diligent shipping sales team to provide suitable doorstep shipping service and also offer all legal documents.

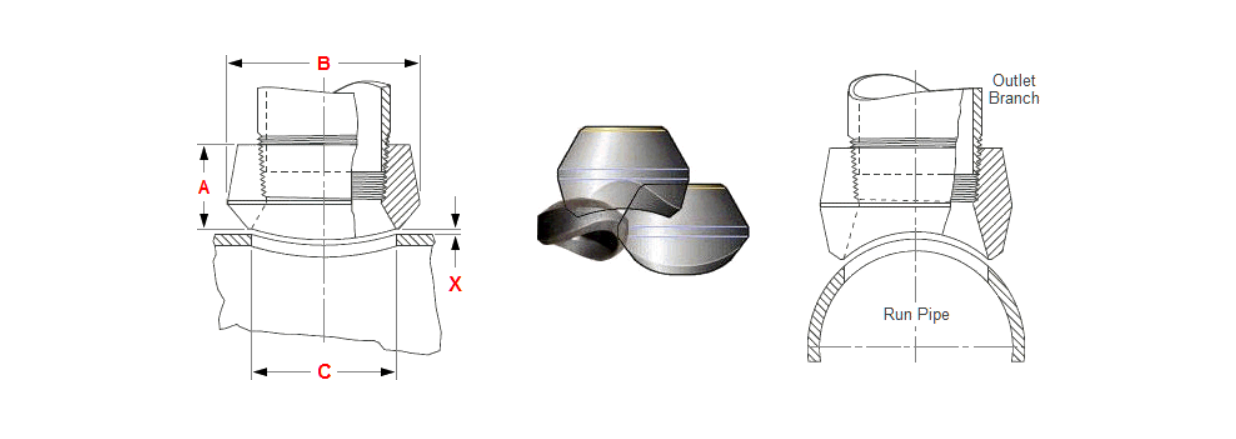

Stainless Steel 304H Threadolet is utilized in 90-degree self-reinforcing branch, and available in two types such as reduced size and full size. It has excellent tensile strength referable for small branch pipe connections. It shows life-long durability, corrosion resistant form various corrosive agent present in the harsh atmosphere and exhibits good formability. Our 1.4948 Threadolet is available in different alloys and grades to make it reliable in various reducing conditions and hostile environments. We are providing S30409 Threadolet that has higher tensile strength, robustness, anti-corrosiveness, higher durability, excellent weldability and longer working life. MetalX Engineering Inc is supplying SS304H Threadolet in various sizes, materials, grades, standards and dimensions as per the industrial needs. We have well-equipped manufacturing plant to fulfil all demands of the client in the minimum time. We are utilizing the top-notch quality raw materials to manufacture a sensible quality 304H Threadolet which can survive in harsh media to provide life-long service to our customer.

| NPS | A | B | C |

| 1/2 | 1 25.40 |

1.13/32 35.71 |

15/16 23.81 |

| 3/4 | 1.1/16 26.98 |

1.23/32 43.65 |

1.5/32 29.36 |

| 1 | 1.5/16 33.33 |

2 50.80 |

1.7/16 36.51 |

| 1.1/4 | 1.5/16 33.33 |

2.9/16 65.08 |

1.3/4 44.45 |

| 1.1/2 | 1.3/8 34.92 |

2.27/32 72.23 |

2 50.80 |

| 2 | 1.1/2 38.10 |

3.15/32 88.10 |

2.9/16 65.08 |

| 2.1/2 | 1.13/16 46.03 |

4.1/16 103.18 |

3 76.20 |

| 3 | 2 50.80 |

4.13/16 122.23 |

3.11/16 93.66 |

| 3.1/2 | 2.1/8 53.975 |

5.7/32 132.55 |

4 101.6 |

| 4 | 2.1/4 57.15 |

5.31/32 151.60 |

4.3/4 120.65 |

| 5 | 2.5/8 66.67 |

7.5/16 185.73 |

5.9/16 141.28 |

| 6 | 2.3/4 69.85 |

8.5/8 219.07 |

6.11/16 169.86 |

| NPS | A | B | C |

| 1/2 | 1.1/4 31.75 |

1.23/32 43.65 |

3/4 19.05 |

| 3/4 | 1.7/16 36.51 |

1.61/64 49.60 |

1 25.40 |

| 1 | 1.9/16 39.68 |

2.7/16 61.91 |

1.5/16 33.33 |

| 1.1/4 | 1.5/8 41.27 |

2.23/32 69.05 |

1.1/2 38.10 |

| 1.1/2 | 1.11/16 42.86 |

3.1/4 82.55 |

1.15/16 49.21 |

| 2 | 2.1/16 52.38 |

4.1/32 102.39 |

2.3/4 69.85 |

BRIGHT

POLISHED

COATED

MATT FINISH

Countries we export to:304H Threadolet Manufacturers / Suppliers / Stockist in Kuwait, 304H Threadolet Manufacturers in UAE, 304H Threadolet Manufacturers in Germany, 304H Threadolet Manufacturers in Saudi Arabia, 304H Threadolet Manufacturers in West Africa, 304H Threadolet Manufacturers in Iraq, 304H Threadolet Manufacturers in Congo, 304H Threadolet Manufacturers in Mexico, 304H Threadolet Manufacturers in Bahrain, 304H Threadolet Manufacturers in Canada, 304H Threadolet Manufacturers in Philippines, 304H Threadolet Manufacturers in Thailand, 304H Threadolet Manufacturers in Kenya, 304H Threadolet Manufacturers in Oman, 304H Threadolet Manufacturers in Malaysia, 304H Threadolet Manufacturers in Turkey, 304H Threadolet Manufacturers in Qatar, 304H Threadolet Manufacturers in Sudan, 304H Threadolet Manufacturers in Netherlands, 304H Threadolet Manufacturers in Oman, 304H Threadolet Manufacturers in Nigeria, 304H Threadolet Manufacturers in Lithuania, 304H Threadolet Manufacturers in Gabon, 304H Threadolet Manufacturers in Russia, 304H Threadolet Manufacturers in Vietnam, 304H Threadolet Manufacturers in Angola, 304H Threadolet Manufacturers in Bolivia, 304H Threadolet Manufacturers in Indonesia, 304H Threadolet Manufacturers in UK, 304H Threadolet Manufacturers in Yemen, 304H Threadolet Manufacturers in Italy, 304H Threadolet Manufacturers in United States, 304H Threadolet Manufacturers in Venezuela, 304H Threadolet Manufacturers in Spain, 304H Threadolet Manufacturers in Iran, 304H Threadolet Manufacturers in Estonia, 304H Threadolet Manufacturers in Kazakhstan, 304H Threadolet Manufacturers in Algeria, 304H Threadolet Manufacturers in Jordan, 304H Threadolet Manufacturers in Ecuador, 304H Threadolet Manufacturers in Portugal, 304H Threadolet Manufacturers in Colombia, 304H Threadolet Manufacturers in Libya, 304H Threadolet Manufacturers in Chile, 304H Threadolet Manufacturers in Peru, 304H Threadolet Manufacturers in Iran, 304H Threadolet Manufacturers in South Africa, 304H Threadolet Manufacturers in Bangkok, 304H Threadolet Manufacturers in Namibia, 304H Threadolet Manufacturers in Jeddah, 304H Threadolet Manufacturers in Afghanistan, 304H Threadolet Manufacturers in Israel, 304H Threadolet Manufacturers in Zambia, 304H Threadolet Manufacturers in Macau, 304H Threadolet Manufacturers in Morocco, 304H Threadolet Manufacturers in Denmark, 304H Threadolet Manufacturers in Taiwan, 304H Threadolet Manufacturers in Norway, 304H Threadolet Manufacturers in Belarus, 304H Threadolet Manufacturers in North Macedonia, 304H Threadolet Manufacturers in Lebanon, 304H Threadolet Manufacturers in Sri Lanka, 304H Threadolet Manufacturers in Bhutan, 304H Threadolet Manufacturers in Bulgaria, 304H Threadolet Manufacturers in Albania, 304H Threadolet Manufacturers in Ukraine, 304H Threadolet Manufacturers in Belgium, 304H Threadolet Manufacturers in Finland, 304H Threadolet Manufacturers in Slovokia, 304H Threadolet Manufacturers in Tibet, 304H Threadolet Manufacturers in Romania, 304H Threadolet Manufacturers in France, 304H Threadolet Manufacturers in Brazil, 304H Threadolet Manufacturers in Trinidad & Tobago, 304H Threadolet Manufacturers in Fiji, 304H Threadolet Manufacturers in Tunisia, 304H Threadolet Manufacturers in Gambia, 304H Threadolet Manufacturers in Mexico, 304H Threadolet Manufacturers in Hungary, 304H Threadolet Manufacturers in Zimbabwe, 304H Threadolet Manufacturers in Mongolia, 304H Threadolet Manufacturers in Ghana, 304H Threadolet Manufacturers in Egypt, 304H Threadolet Manufacturers in Kazakhstan, 304H Threadolet Manufacturers in Czech Republic, 304H Threadolet Manufacturers in Azerbaijan, 304H Threadolet Manufacturers in Poland, 304H Threadolet Manufacturers in Greece, 304H Threadolet Manufacturers in Costa Rica, 304H Threadolet Manufacturers in Kosovo, 304H Threadolet Manufacturers in New Zealand, 304H Threadolet Manufacturers in Croatia, 304H Threadolet Manufacturers in Puerto Rico, 304H Threadolet Manufacturers in Tanzania, 304H Threadolet Manufacturers in Somalia.

Major Exporting Areas: 304H Threadolet Manufacturers / Suppliers / Stockist in Moscow, Port-Of-Spain, Seoul, Montreal, Dubai, Kuala Lumpur, Aberdeen, Tehran, Bogota, Petaling Jaya, Melbourne, Abu Dhabi, Courbevoie, Edmonton, Ho Chi Minh City, Bangkok, Toronto, Muscat, Milan, Busan, Mexico City, Perth, La Victoria, Santiago, Rio de Janeiro, London, Karachi, Los Angeles, Manama, Geoje-si, Atyrau, Sydney, Riyadh, New York, Jeddah, Houston, Granada, Jakarta, Brisbane, Algiers, Kuwait City, Dubai, Hanoi, Doha, Al Jubail, Chiyoda, Cairo, Gimhae-si, Caracas, Lagos, Al Khobar, Madrid, Singapore, Calgary, Colombo, Ulsan, Istanbul, Ahvaz, Dammam, Dallas, Texas, Ankara, Sharjah, Vung Tau, Angola, Benin, Burundi, Botswana, Burkina Faso, Cameroon, Douala, Central African Republic, Republic of Congo, Democratic Republic of Congo, Côte d'Ivoire, Djibouti, Eritrea, Ethiopia, Equatorial Guinea, Gabon, Guinea, Kenya, Liberia,Malawi, Mali, Mauritania, Mauritius, Casablanca-Settat, Tanger-Tetouan-Al Hoceima, Fès-Meknès, Marrakesh-Safi, Oriental, Béni Mellal-Khénifra, Souss-Massa, Laâyoune-Sakia El Hamra, Rabat-Salé-Kénitra region, Mozambique, Temara, Niger, Rwanda, Senegal, Sierra Leone, Sudan, Tanzania, Togo, Uganda, Bangkok, Bangchan, Khlong Sam Wa, Gemopolis, Lard Krabang, Pathumthani, Bangkadi, Navanakorn, Samut Prakarn, Bangplee, Bangpoo, Saraburi, Nongkhae, SIL I/Land, Chachoengsao, Alloy 20 I/P, Gateway City, Wellgrow, Rayong, Amata City, Eastern Seaboard, Hemaraj Eastern Seaboard, Rojana, Soam Eastern, Chonburi, Amata Nakorn, Hemaraj Chonburi, Pinthong, Ayutthaya, Bangpa-in, Saha Ratna Nakorn, Nakornratchasima, Kabinburi, Prachinburi, HCMC, Tan Thuan Export Processing Zone, Bien Hoa, Dong Nai Province, Amata City Bien Hoa Industrial Park, Long Binh Techno Park, Binh Duong Province, Vietnam Singapore Industrial Park, My Phuoc Industrial Park, Ho Nai Industrial Zone, Bau Xeo Industrial Park, Long Thanh Industrial Zone, Long Duc Industrial Park, Duc Hao I, Tan Huong, Long Jiang, Tra Noc I/II, Hung Phu I, Hiep Phuoc Industrial Park, Phuoc Dong Industrial Park, Dinh Vu – Cat Hai Economic Zone.

Copyright © 2012 - All Rights Reserved - MetalX Engineering Inc

SPECIFICATIONS

ASTM / ASME

MSS SP-97, MSS SP-95, 83, 95, 97, BS 3799, ASME B16.11

1/2" to 24"

#3000 LBS, #6000 LBS, #9000 LBS